Introduction

Carbon Capture (CC) is widely recognized as a key enabling technology for industrial decarbonization. Yet, its high energy cost and uncertain energy markets hinder large-scale deployment in Flanders’ industry. Even with optimized heat integration and future electrification, industrial sectors such as refining, chemicals, steel, cement, and waste-to-energy continue to release large volumes of unused low-grade thermal energy. HEATCAP aims to address this…

The P2PC project aspires to cope with the urgent issue of plastics waste management. The project targets the challenge of increasing plastic waste volumes and diversity on the one hand, as well as the establishment of circular material schemes instead of value destruction. The most important premise of P2PC is that by pyrolysis, plastic waste that is currently being burned or landfilled can be a source of diverse chemical building blocks, the so-called “precious chemicals”.…

Goal of the TRUCE project is, first of all, to develop new building blocks for highly functional, flexible packaging solutions that can be combined into fully recyclable mono-polyethylene (≥95% PE) structures. The combined expertise of packaging design from Amcor, polyethylene production, design and recycling activities from Borealis, specialty additives from Eastman, adhesives from Bostik, packaging line and food product requirements from Puratos and recyclability testing and predictive…

The aim of the PROFIT-project is the valorization of plastic materials from complex waste streams to qualitative end-products. The whole value chain, from waste to separation, to final processing will be examined. Two research areas are key within this project:

- Reverse engineering: a cost-effective separation fit-for-use, starting from the desired properties of the final product.

- Gaining more fundamental knowledge on the behavior of post-consumer plastic waste in…

Many chemical companies are nowadays confronted with very challenging liquid separations, aiming at separating molecules with very similar physical properties. The current trend towards more bio-based and/or highly-tailored chemicals, will only increase the number of these demanding separations. These challenges would benefit from efficient Affinity Separations (AS). The most traditional AS technology is liquid-…

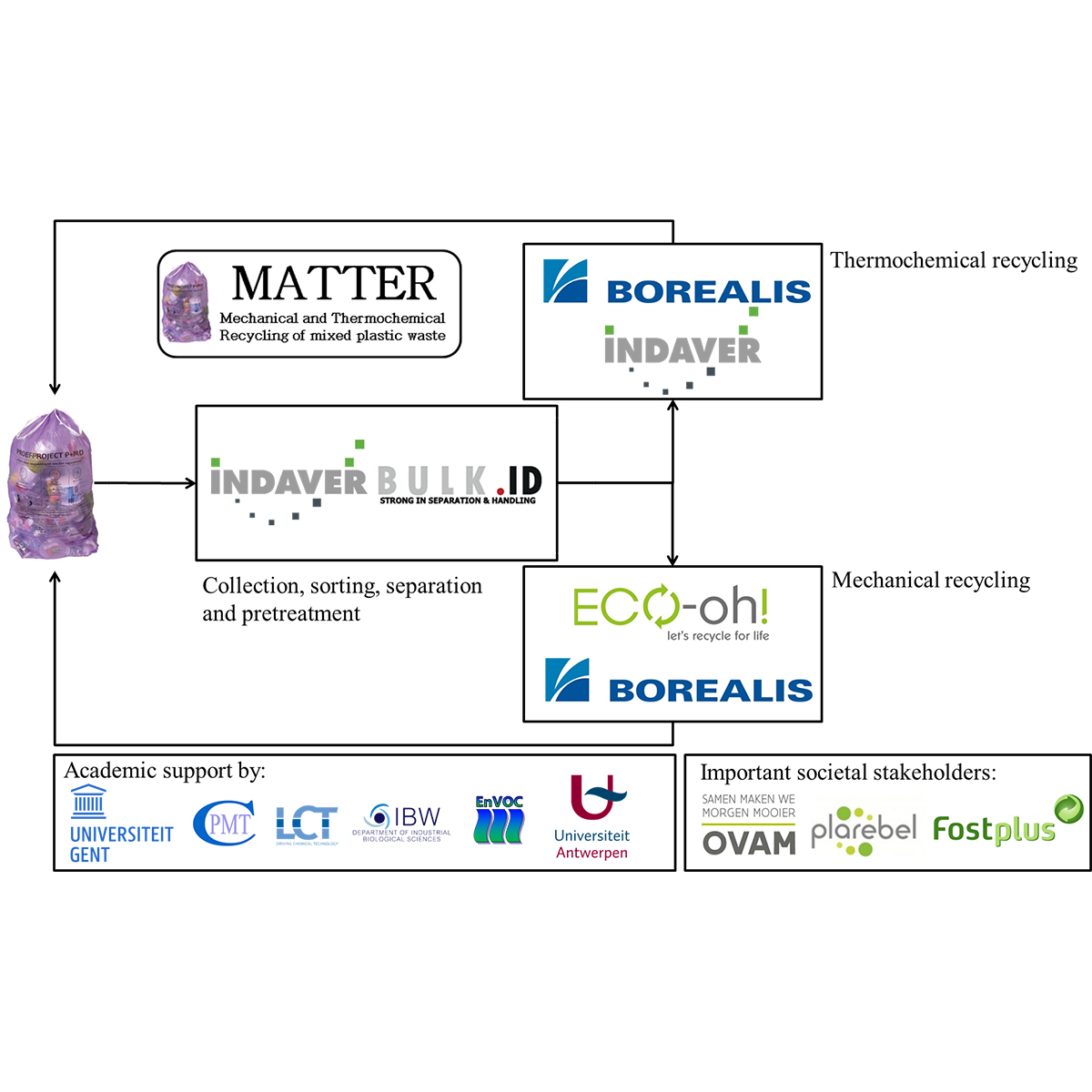

The WATCH project aims at the development and demonstration of a new disruptive technology for the conversion of plastic waste to chemicals via catalytic fast pyrolysis based on an innovative reactor concept. The latter technology will be benchmarked against classic, state-of-the-art pyrolysis technology and a sustainability assessment will be performed. Four plastic waste streams will be investigated: mixed polyolefinic waste, multilayer packaging, PS…

The possibility to capture CO2 at point sources, which account for 45% of the emissions in Europe, and transforming it into added-value products, is gaining attention. The steel industry sector is one of the largest GHG contributors. In their strive for GHG emission reduction, strategies such as improvements in energy efficiency, resource recycling, utilization and recovery have already been implemented, but further emission reduction can only be achieved by capturing CO2 emissions…

All renewable CCU based on formic acid integrated in an industrial microgrid

The main objective of the project is the development of technologies for the conversion of CO<sub>2</sub> to value-added chemicals using catalysis and renewable energy. To benchmark, compare and develop the various technologies, the formation of formic acid was selected as the initial target. Formic acid is the first product of the hydrogenation of CO2towards value-added chemicals. In the…