Introduction

Carbon Capture (CC) is widely recognized as a key enabling technology for industrial decarbonization. Yet, its high energy cost and uncertain energy markets hinder large-scale deployment in Flanders’ industry. Even with optimized heat integration and future electrification, industrial sectors such as refining, chemicals, steel, cement, and waste-to-energy continue to release large volumes of unused low-grade thermal energy. HEATCAP aims to address this dual challenge by enabling carbon capture solutions that can operate efficiently on low-temperature waste heat. The project is highly relevant for industrial operators facing rising carbon costs, policymakers pursuing climate targets, and society seeking affordable decarbonization pathways that preserve industrial competitiveness and employment.

Goal

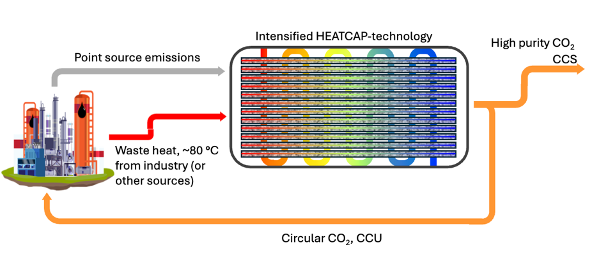

The primary goal of HEATCAP is to enable a new generation of low-energy and cost-effective carbon capture technologies for point source emissions with CO2 concentrations between 5 and 30%. By structurally relying on low-grade waste heat instead of premium energy carriers, the project aims to significantly reduce energy consumption and total capture cost for a broad range of industrial applications. HEATCAP targets capture costs below 50 € per ton CO₂ while maintaining industrially relevant performance and CO₂ quality. Validation under industrial conditions will position carbon capture as a realistic and scalable decarbonization option for the Flemish industry.

Approach

HEATCAP achieves cost and energy reductions through process intensification at three levels. First, an adsorption-based separation process with rapid regeneration cycles is developed, primarily using waste heat below 90°C. Second, equipment design is intensified through advanced heat-exchange geometries and durable adsorbent coatings integrated into compact, scalable units. Third, tailored adsorption materials ensure efficient CO2 capture, also under humid operating conditions. System performance is optimized through iterative modeling, experimental validation, and real-context integration studies, progressing from lab-scale components to an early system prototype tested under industrially relevant conditions. Close collaboration between research partners with complementary expertise and various industrial stakeholders ensures that technical feasibility, economic viability, scalability, and plant-level integration are addressed in parallel.

Expected impact and valorization

HEATCAP is expected to advance sustainable, adsorption-based carbon capture under industrial conditions. Compared to the amine-based benchmark, it anticipates up to 40% lower capture cost, 50% lower OPEX, and scalable CO2 emission reductions with 25% lower carbon footprint. These benefits reduce deployment barriers, support industrial continuity and employment, and strengthen compliance under EU ETS. HEATCAP results will be valorized through IP protection and targeted industrial uptake of the validated capture process and system design, leading to future commercial CC solutions. The integrated modular device, advanced materials, and industrial integration studies will translate to licensable products, consultancy services, and decision- support tools. The early system prototype will de-risk industrial pilot investments, enable scale- up, potential spin-offs, and accelerate rollout in CCUS value chains.

HEATCAP CONSORTIUM

- VUB – Department of Chemical Engineering – CHIS (Prof. Joeri Denayer – project coordinator)

- UGent – Department of Organic and Macromolecular Chemistry – SSG (Prof. Frédéric Lynen)

- KU Leuven – Center for Sustainable Catalysis and Engineering - CSCE (Prof. Michiel Dusselier)

- VUB – Centre for Environment, Economy, Energy – C3E (Prof. Sebastian Oberthür)

- KU Leuven – Innovative Design for Energy Applications Lab – IDEAL (Prof. Maarten Blommaert)

HEATCAP’s Industrial Advisory Board holds over 20 stakeholders representing industrial CO₂ emitters, waste heat generators and operators, technology providers, engineering firms, and key actors in the CCUS ecosystem.

Interested to know more : contact business developer Marleen Claeys by mail or +32479174798