Clearly, the EU needs to develop the capability to deal with its plastic waste. Waste materials, duly collected in Western Europe, should not be sent overseas and should be recycled locally, preferably in closed loop cycles. To enhance such high end recycling schemes, it might be required in some cases to clean the plastics up to a level that even the additives are removed; think of flame retardants, phthalates, metal based stabilizers, etc.

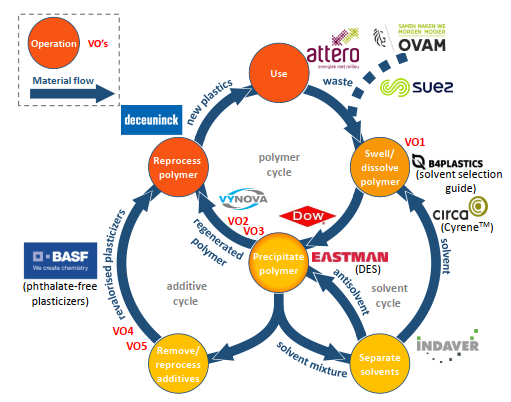

SOLVATION proposes an integrated approach to revalorization of end-of-life polymers loaded with problematic additives, in particular PVC and PE/PP. SOLVATION will realise a TRIPLE CYCLE:

- We aim at recovering the intact original polymer chains, i.e. with minimal or even without degradation of the chemical structure, allowing re-use in new products; this results in a POLYMER CYCLE;

- The downstream processing of the additives, e.g. the sequestration of the toxic metals, or the catalytic transformation of the problematic additives, proceeds as much as possible in the same solvent as used to dissolve the polymer; the solvents used for polymer swelling/dissolution can be fully recovered for a next cycle, in an energy-efficient overall process; this results in a SOLVENT CYCLE;

- The catalytic transformation allows to re-use safe, modified additives in new products; or the reaction products can be fully integrated in new value chains; this results in an ADDITIVE CYCLE